Introduction:

In our rapidly advancing digital age, the proliferation of electronic devices has brought about significant challenges in waste management. E-waste, or electrical waste, encompasses discarded electronic appliances such as computers, mobile phones, televisions, and other gadgets. The growing volume of e-waste has become a critical issue, necessitating effective electronics waste recycling to mitigate environmental impact and health hazards.At JR Recycling Solution Ltd, we are committed to addressing this growing problem through innovative electronics waste recycling practices. Our mission is to lead the way in waste management e-waste solutions, highlighting the importance of e-waste recycling for a sustainable future.

The Scope of E-Waste

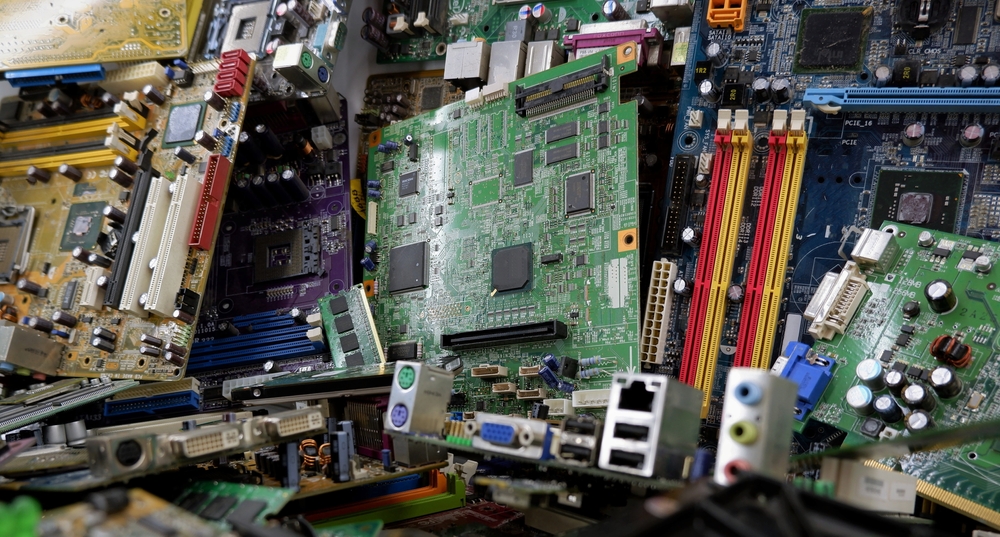

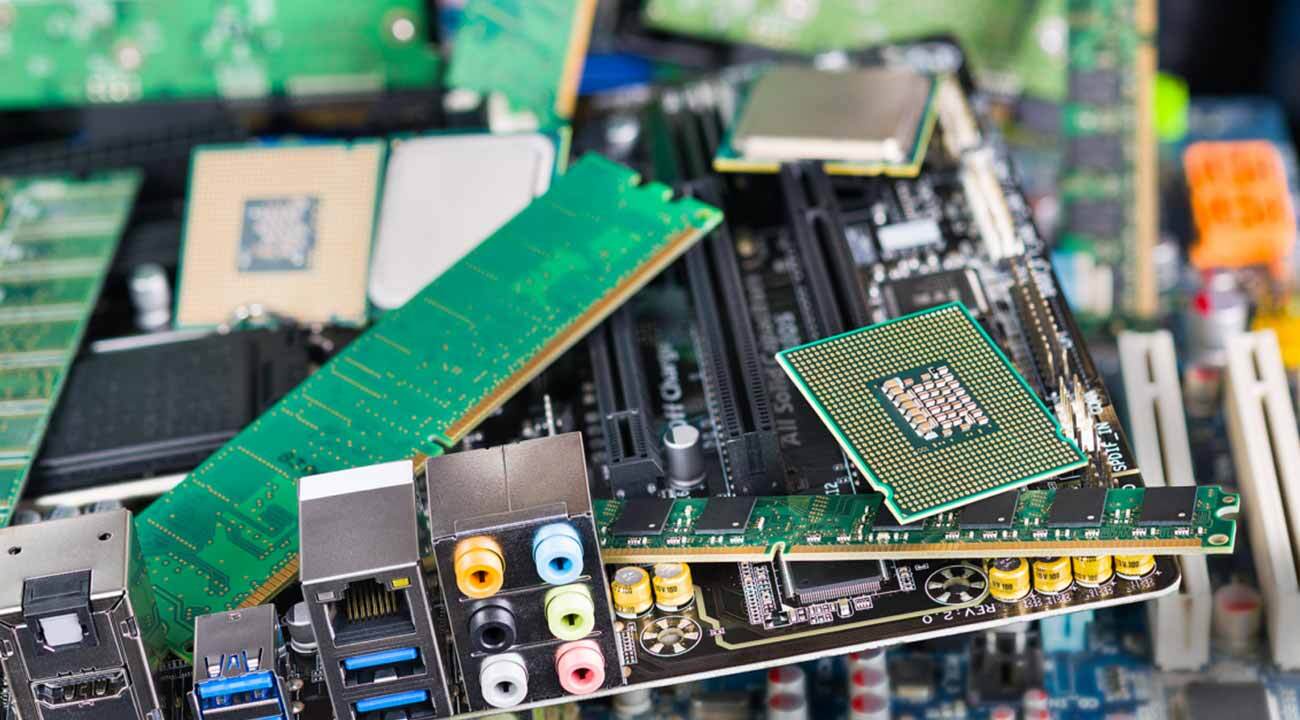

E-waste is one of the fastest-growing waste streams globally. According to recent statistics, the world generated approximately 53.6 million metric tons of e-waste in 2019, with projections indicating a rise to 74 million metric tons by 2030. This exponential growth is driven by increased consumer demand, shorter life cycles of electronic devices, and rapid technological advancements.

Importance of E-Waste Recycling

The importance of e-waste recycling cannot be overstated. E-waste contains hazardous materials such as lead, mercury, and cadmium, which can cause significant environmental damage if not managed properly. Additionally, these toxic substances pose serious health risks, including respiratory issues and neurological damage. Effective electronics waste recycling is essential to mitigate these dangers, ensuring that harmful materials are safely processed and valuable resources are recovered.

In our rapidly advancing technological world, electronic devices are becoming indispensable in everyday life. From smartphones and laptops to household appliances and medical equipment, the proliferation of electronic devices has led to a parallel surge in electronic waste, or e-waste. E-waste recycling is not just a responsible practice but an essential one, with far-reaching implications for the environment, public health, and the economy.

Environmental Protection

One of the most significant reasons for recycling e-waste is its environmental impact. Electronic devices often contain hazardous materials such as lead, mercury, cadmium, and brominated flame retardants. When improperly disposed of, these toxic substances can leach into the soil and groundwater, causing severe environmental contamination. E-waste recycling helps mitigate this risk by ensuring that hazardous materials are safely extracted and disposed of, preventing soil and water pollution.

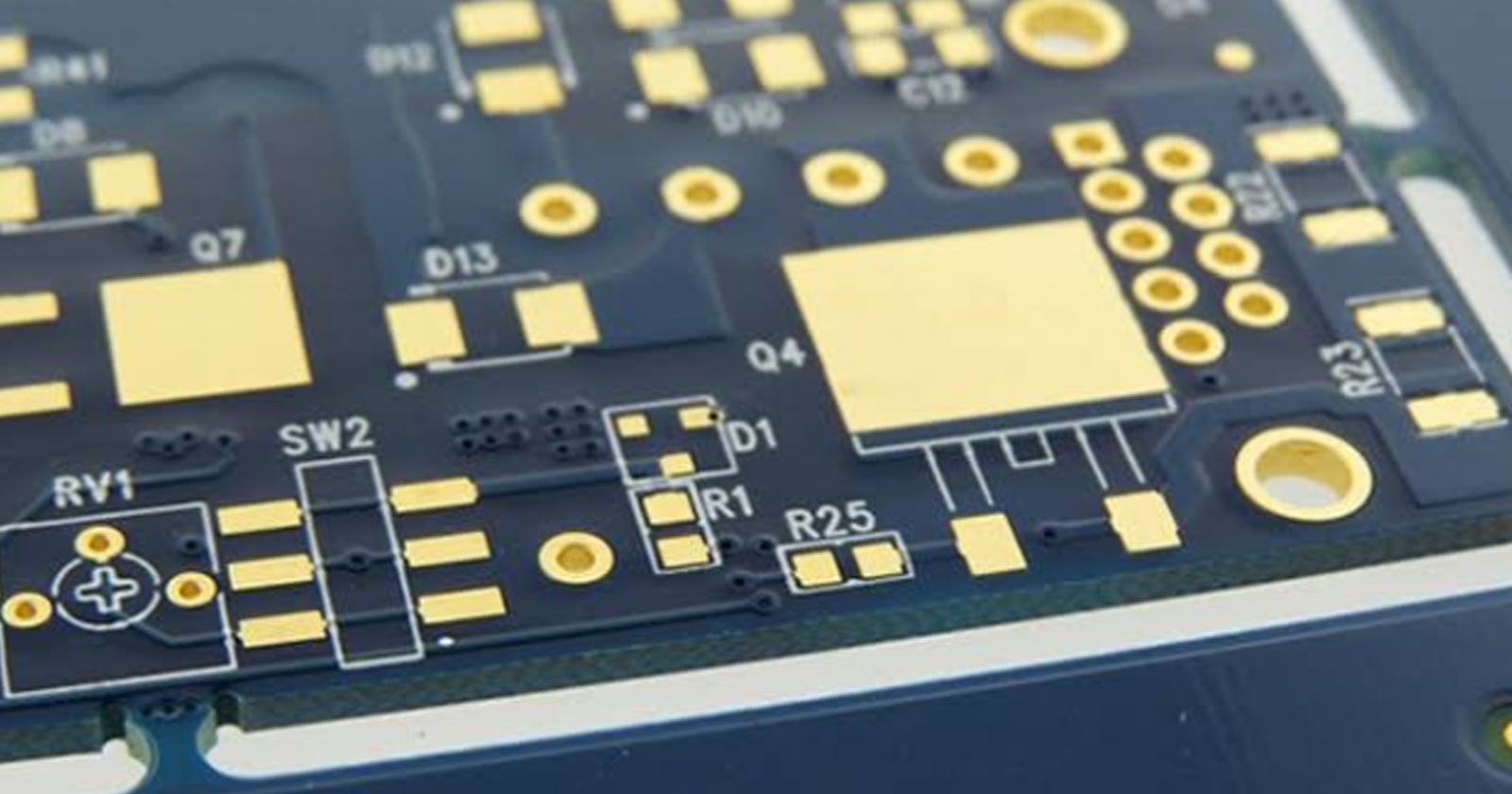

Moreover, recycling e-waste reduces the need for raw material extraction, conserving natural resources. Many electronic devices contain valuable metals such as gold, silver, and copper. By recovering these materials through recycling, we can decrease the environmental degradation associated with mining and reduce greenhouse gas emissions from manufacturing processes.

Public Health Benefits

The improper handling and disposal of e-waste pose serious health risks. Exposure to the toxic components in e-waste can lead to severe health issues, including respiratory problems, neurological damage, and various cancers. This is particularly concerning in developing countries where informal e-waste recycling operations often involve unsafe practices, such as open-air burning and acid baths, to recover valuable materials.

By establishing formal e-waste recycling programs with strict safety protocols, we can protect workers and communities from these hazardous exposures. Proper recycling processes ensure that harmful substances are managed in ways that minimize health risks, contributing to a healthier population.

Economic Advantages

E-waste recycling also offers significant economic benefits. Recovering valuable metals and components from discarded electronics can reduce the costs associated with manufacturing new products. For instance, extracting metals from recycled electronics is often less expensive and less environmentally damaging than mining virgin materials. This not only lowers production costs but also stabilizes supply chains for critical materials.

Furthermore, the e-waste recycling industry creates job opportunities. As the volume of e-waste continues to grow, so does the demand for skilled workers in recycling facilities. This includes roles in collection, transportation, sorting, and processing of electronic waste. Investing in e-waste recycling infrastructure can stimulate economic growth by creating a new sector dedicated to sustainable practices.

Legal and Ethical Responsibility

Many countries have recognized the importance of e-waste recycling and have implemented regulations mandating the proper disposal and recycling of electronic waste. Compliance with these laws is not only a legal obligation but also an ethical one. Manufacturers and consumers alike have a responsibility to ensure that their electronic devices are disposed of in a way that does not harm the environment or public health.

Corporate responsibility initiatives often include e-waste recycling programs as part of their sustainability goals. By participating in these programs, companies can enhance their reputation, meet regulatory requirements, and contribute to global environmental conservation efforts.

Environmental and Health Impacts

The improper disposal of e-waste poses severe environmental and health risks. E-waste contains hazardous substances like lead, mercury, cadmium, and brominated flame retardants. When these toxic materials leach into the soil and groundwater, they can cause significant environmental damage. Furthermore, exposure to these substances can lead to serious health issues, including respiratory problems, skin disorders, and neurological damage.

Our Approach to Waste Management E-Waste

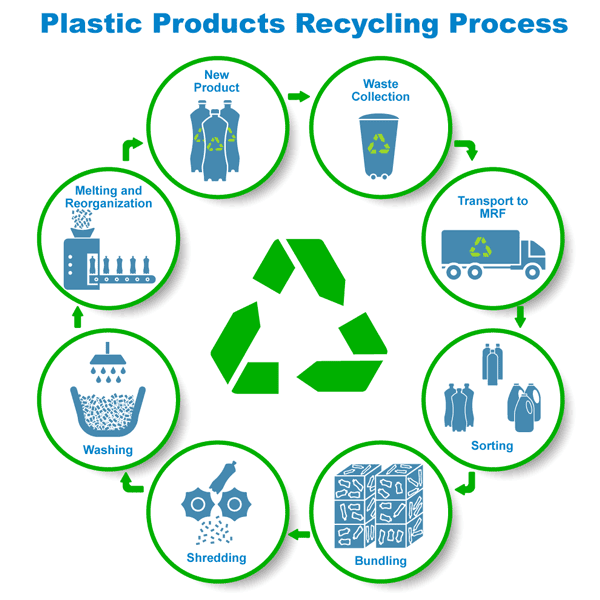

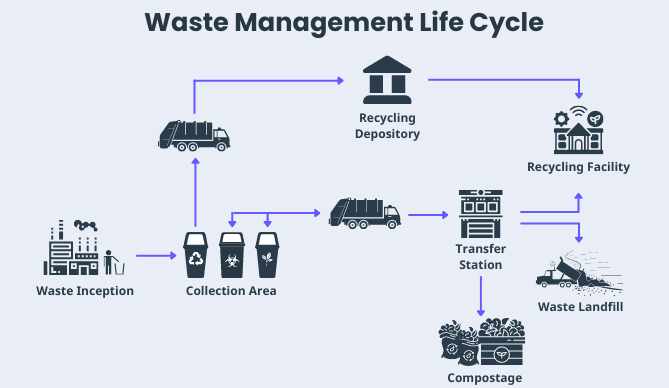

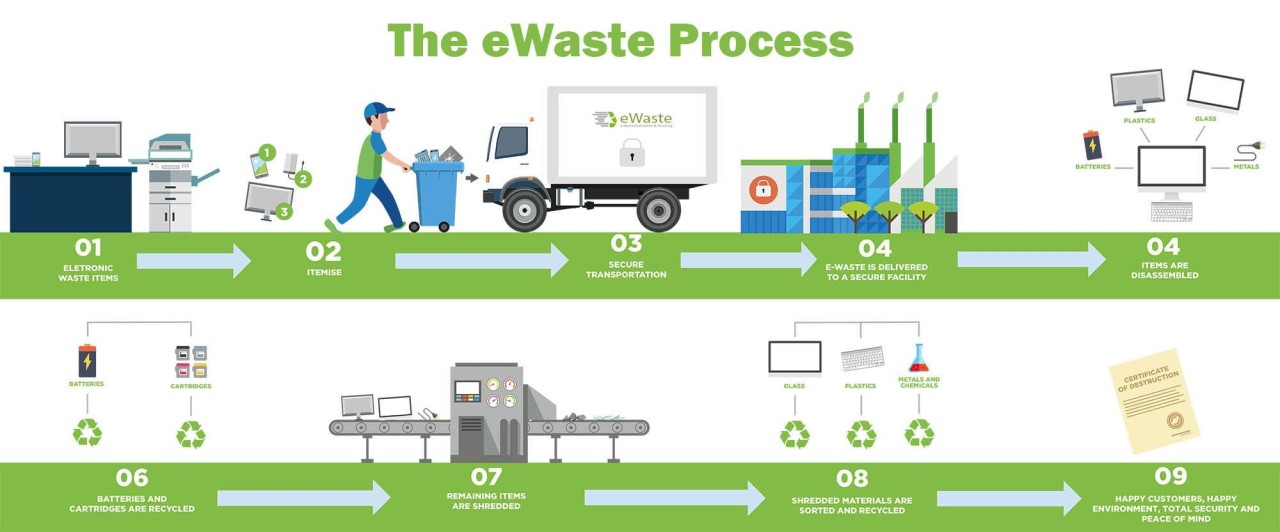

At JR Recycling Solution Ltd, we adopt a comprehensive approach to e-waste management, focusing on sustainability and efficiency. Our services encompass the entire lifecycle of electronic products, from collection and sorting to recycling and disposal. Here’s how we manage the process:

- Collection and Sorting: We provide convenient collection services for households and businesses, ensuring that e-waste is gathered efficiently. Our sorting process separates different types of e-waste, facilitating more effective recycling.

- Advanced Recycling Techniques: Utilizing state-of-the-art recycling technologies, we recover valuable materials such as gold, silver, copper, and rare earth elements from discarded electronics. These materials can then be reused in the manufacturing of new products, reducing the need for virgin resource extraction.

- Safe Disposal of Hazardous Materials: We adhere to strict environmental standards to safely dispose of hazardous substances found in e-waste. Our processes prevent these toxins from contaminating the environment, protecting both ecosystems and human health.

- Consumer Education and Awareness: We believe that informed consumers are key to effective e-waste management. Through educational campaigns and community outreach, we encourage responsible disposal of electronic devices and promote the benefits of recycling. Effective Waste Management E-Waste Practices

Effective waste management strategies are essential for addressing the e-waste challenge. Several approaches can be implemented to enhance the efficiency of electronics waste recycling:

- Extended Producer Responsibility (EPR): EPR policies hold manufacturers accountable for the entire lifecycle of their products, including end-of-life disposal. By incorporating recycling costs into the product price, producers are incentivized to design more sustainable and recyclable electronics.

- Consumer Awareness and Participation: Educating consumers about the importance of e-waste recycling and providing convenient recycling options can significantly increase participation rates. Collection drives, drop-off points, and take-back programs are effective ways to encourage consumers to dispose of their e-waste responsibly.

- Regulatory Frameworks: Governments play a vital role in regulating e-waste management. Implementing stringent regulations and standards for e-waste disposal and recycling ensures that these activities are conducted in an environmentally sound manner. Moreover, enforcing penalties for non-compliance can deter illegal dumping and encourage proper recycling practices.

- Technological Innovations: Advancements in recycling technologies can enhance the efficiency and effectiveness of e-waste recycling processes. Innovative techniques such as hydrometallurgical and pyrometallurgical methods, as well as automated sorting systems, can improve material recovery rates and reduce environmental impacts.

The Role of Stakeholders in E-Waste Management

Effective e-waste management requires collaboration among various stakeholders, including manufacturers, consumers, recyclers, and regulators. At JR Recycling Solution Ltd, we work closely with all stakeholders to create a sustainable e-waste ecosystem:

Manufacturers: We partner with manufacturers to develop eco-friendly product designs and recycling programs that facilitate easier end-of-life processing.

Consumers: By offering easy access to recycling services and educating the public on the importance of e-waste recycling, we empower consumers to make environmentally responsible choices.

Regulators: We comply with all relevant regulations and advocate for stronger e-waste management policies to ensure a greener future.

Conclusion

JR Recycling Solution Ltd. stands at the forefront of e-waste management, delivering innovative, sustainable, and effective solutions to tackle the growing challenge of electronic waste. Through our comprehensive e-waste management system, we prioritize environmental responsibility, ensuring the safe and efficient recycling of electronic products. Our approach not only mitigates the harmful impact of e-waste on the environment but also recovers valuable materials, contributing to the circular economy. By fostering partnerships with businesses, governments, and communities, we are committed to raising awareness and promoting practices that support a cleaner, greener future. JR Recycling Solution Ltd. is dedicated to continuous improvement and innovation in e-waste management, reaffirming our role as a leader in sustainable recycling practices. Together, we can make a significant difference in preserving our planet for future generations.

Introduction:

In our rapidly advancing digital age, the proliferation of electronic devices has brought about significant challenges in waste management. E-waste, or electrical waste, encompasses discarded electronic appliances such as computers, mobile phones, televisions, and other gadgets. The growing volume of e-waste has become a critical issue, necessitating effective electronics waste recycling to mitigate environmental impact and health hazards.At JR Recycling Solution Ltd, we are committed to addressing this growing problem through innovative electronics waste recycling practices. Our mission is to lead the way in waste management e-waste solutions, highlighting the importance of e-waste recycling for a sustainable future.

The Scope of E-Waste

E-waste is one of the fastest-growing waste streams globally. According to recent statistics, the world generated approximately 53.6 million metric tons of e-waste in 2019, with projections indicating a rise to 74 million metric tons by 2030. This exponential growth is driven by increased consumer demand, shorter life cycles of electronic devices, and rapid technological advancements.

Importance of E-Waste Recycling

The importance of e-waste recycling cannot be overstated. E-waste contains hazardous materials such as lead, mercury, and cadmium, which can cause significant environmental damage if not managed properly. Additionally, these toxic substances pose serious health risks, including respiratory issues and neurological damage. Effective electronics waste recycling is essential to mitigate these dangers, ensuring that harmful materials are safely processed and valuable resources are recovered.

In our rapidly advancing technological world, electronic devices are becoming indispensable in everyday life. From smartphones and laptops to household appliances and medical equipment, the proliferation of electronic devices has led to a parallel surge in electronic waste, or e-waste. E-waste recycling is not just a responsible practice but an essential one, with far-reaching implications for the environment, public health, and the economy.

Environmental Protection

One of the most significant reasons for recycling e-waste is its environmental impact. Electronic devices often contain hazardous materials such as lead, mercury, cadmium, and brominated flame retardants. When improperly disposed of, these toxic substances can leach into the soil and groundwater, causing severe environmental contamination. E-waste recycling helps mitigate this risk by ensuring that hazardous materials are safely extracted and disposed of, preventing soil and water pollution.

Moreover, recycling e-waste reduces the need for raw material extraction, conserving natural resources. Many electronic devices contain valuable metals such as gold, silver, and copper. By recovering these materials through recycling, we can decrease the environmental degradation associated with mining and reduce greenhouse gas emissions from manufacturing processes.

Public Health Benefits

The improper handling and disposal of e-waste pose serious health risks. Exposure to the toxic components in e-waste can lead to severe health issues, including respiratory problems, neurological damage, and various cancers. This is particularly concerning in developing countries where informal e-waste recycling operations often involve unsafe practices, such as open-air burning and acid baths, to recover valuable materials.

By establishing formal e-waste recycling programs with strict safety protocols, we can protect workers and communities from these hazardous exposures. Proper recycling processes ensure that harmful substances are managed in ways that minimize health risks, contributing to a healthier population.

Economic Advantages

E-waste recycling also offers significant economic benefits. Recovering valuable metals and components from discarded electronics can reduce the costs associated with manufacturing new products. For instance, extracting metals from recycled electronics is often less expensive and less environmentally damaging than mining virgin materials. This not only lowers production costs but also stabilizes supply chains for critical materials.

Furthermore, the e-waste recycling industry creates job opportunities. As the volume of e-waste continues to grow, so does the demand for skilled workers in recycling facilities. This includes roles in collection, transportation, sorting, and processing of electronic waste. Investing in e-waste recycling infrastructure can stimulate economic growth by creating a new sector dedicated to sustainable practices.

Legal and Ethical Responsibility

Many countries have recognized the importance of e-waste recycling and have implemented regulations mandating the proper disposal and recycling of electronic waste. Compliance with these laws is not only a legal obligation but also an ethical one. Manufacturers and consumers alike have a responsibility to ensure that their electronic devices are disposed of in a way that does not harm the environment or public health.

Corporate responsibility initiatives often include e-waste recycling programs as part of their sustainability goals. By participating in these programs, companies can enhance their reputation, meet regulatory requirements, and contribute to global environmental conservation efforts.

Environmental and Health Impacts

The improper disposal of e-waste poses severe environmental and health risks. E-waste contains hazardous substances like lead, mercury, cadmium, and brominated flame retardants. When these toxic materials leach into the soil and groundwater, they can cause significant environmental damage. Furthermore, exposure to these substances can lead to serious health issues, including respiratory problems, skin disorders, and neurological damage.

Our Approach to Waste Management E-Waste

At JR Recycling Solution Ltd, we adopt a comprehensive approach to e-waste management, focusing on sustainability and efficiency. Our services encompass the entire lifecycle of electronic products, from collection and sorting to recycling and disposal. Here’s how we manage the process:

1. Collection and Sorting: We provide convenient collection services for households and businesses, ensuring that e-waste is gathered efficiently. Our sorting process separates different types of e-waste, facilitating more effective recycling.

2. Advanced Recycling Techniques: Utilizing state-of-the-art recycling technologies, we recover valuable materials such as gold, silver, copper, and rare earth elements from discarded electronics. These materials can then be reused in the manufacturing of new products, reducing the need for virgin resource extraction.

3. Safe Disposal of Hazardous Materials: We adhere to strict environmental standards to safely dispose of hazardous substances found in e-waste. Our processes prevent these toxins from contaminating the environment, protecting both ecosystems and human health.

4. Consumer Education and Awareness: We believe that informed consumers are key to effective e-waste management. Through educational campaigns and community outreach, we encourage responsible disposal of electronic devices and promote the benefits of recycling.

Effective Waste Management E-Waste Practices

Effective waste management strategies are essential for addressing the e-waste challenge. Several approaches can be implemented to enhance the efficiency of electronics waste recycling:

1. Extended Producer Responsibility (EPR): EPR policies hold manufacturers accountable for the entire lifecycle of their products, including end-of-life disposal. By incorporating recycling costs into the product price, producers are incentivized to design more sustainable and recyclable electronics.

2. Consumer Awareness and Participation: Educating consumers about the importance of e-waste recycling and providing convenient recycling options can significantly increase participation rates. Collection drives, drop-off points, and take-back programs are effective ways to encourage consumers to dispose of their e-waste responsibly.

3. Regulatory Frameworks: Governments play a vital role in regulating e-waste management. Implementing stringent regulations and standards for e-waste disposal and recycling ensures that these activities are conducted in an environmentally sound manner. Moreover, enforcing penalties for non-compliance can deter illegal dumping and encourage proper recycling practices.

4. Technological Innovations: Advancements in recycling technologies can enhance the efficiency and effectiveness of e-waste recycling processes. Innovative techniques such as hydrometallurgical and pyrometallurgical methods, as well as automated sorting systems, can improve material recovery rates and reduce environmental impacts.

The Role of Stakeholders in E-Waste Management

Effective e-waste management requires collaboration among various stakeholders, including manufacturers, consumers, recyclers, and regulators. At JR Recycling Solution Ltd, we work closely with all stakeholders to create a sustainable e-waste ecosystem:

- Manufacturers: We partner with manufacturers to develop eco-friendly product designs and recycling programs that facilitate easier end-of-life processing.

- Consumers: By offering easy access to recycling services and educating the public on the importance of e-waste recycling, we empower consumers to make environmentally responsible choices.

- Regulators: We comply with all relevant regulations and advocate for stronger e-waste management policies to ensure a greener future.

Conclusion

JR Recycling Solution Ltd. stands at the forefront of e-waste management, delivering innovative, sustainable, and effective solutions to tackle the growing challenge of electronic waste. Through our comprehensive e-waste management system, we prioritize environmental responsibility, ensuring the safe and efficient recycling of electronic products. Our approach not only mitigates the harmful impact of e-waste on the environment but also recovers valuable materials, contributing to the circular economy. By fostering partnerships with businesses, governments, and communities, we are committed to raising awareness and promoting practices that support a cleaner, greener future. JR Recycling Solution Ltd. is dedicated to continuous improvement and innovation in e-waste management, reaffirming our role as a leader in sustainable recycling practices. Together, we can make a significant difference in preserving our planet for future generations.

Introduction:

In our rapidly advancing digital age, the proliferation of electronic devices has brought about significant challenges in waste management. E-waste, or electrical waste, encompasses discarded electronic appliances such as computers, mobile phones, televisions, and other gadgets. The growing volume of e-waste has become a critical issue, necessitating effective electronics waste recycling to mitigate environmental impact and health hazards.At JR Recycling Solution Ltd, we are committed to addressing this growing problem through innovative electronics waste recycling practices. Our mission is to lead the way in waste management e-waste solutions, highlighting the importance of e-waste recycling for a sustainable future.

The Scope of E-Waste

E-waste is one of the fastest-growing waste streams globally. According to recent statistics, the world generated approximately 53.6 million metric tons of e-waste in 2019, with projections indicating a rise to 74 million metric tons by 2030. This exponential growth is driven by increased consumer demand, shorter life cycles of electronic devices, and rapid technological advancements.

Importance of E-Waste Recycling

The importance of e-waste recycling cannot be overstated. E-waste contains hazardous materials such as lead, mercury, and cadmium, which can cause significant environmental damage if not managed properly. Additionally, these toxic substances pose serious health risks, including respiratory issues and neurological damage. Effective electronics waste recycling is essential to mitigate these dangers, ensuring that harmful materials are safely processed and valuable resources are recovered.

In our rapidly advancing technological world, electronic devices are becoming indispensable in everyday life. From smartphones and laptops to household appliances and medical equipment, the proliferation of electronic devices has led to a parallel surge in electronic waste, or e-waste. E-waste recycling is not just a responsible practice but an essential one, with far-reaching implications for the environment, public health, and the economy.

Environmental Protection

One of the most significant reasons for recycling e-waste is its environmental impact. Electronic devices often contain hazardous materials such as lead, mercury, cadmium, and brominated flame retardants. When improperly disposed of, these toxic substances can leach into the soil and groundwater, causing severe environmental contamination. E-waste recycling helps mitigate this risk by ensuring that hazardous materials are safely extracted and disposed of, preventing soil and water pollution.

Moreover, recycling e-waste reduces the need for raw material extraction, conserving natural resources. Many electronic devices contain valuable metals such as gold, silver, and copper. By recovering these materials through recycling, we can decrease the environmental degradation associated with mining and reduce greenhouse gas emissions from manufacturing processes.

Public Health Benefits

The improper handling and disposal of e-waste pose serious health risks. Exposure to the toxic components in e-waste can lead to severe health issues, including respiratory problems, neurological damage, and various cancers. This is particularly concerning in developing countries where informal e-waste recycling operations often involve unsafe practices, such as open-air burning and acid baths, to recover valuable materials.

By establishing formal e-waste recycling programs with strict safety protocols, we can protect workers and communities from these hazardous exposures. Proper recycling processes ensure that harmful substances are managed in ways that minimize health risks, contributing to a healthier population.

Economic Advantages

E-waste recycling also offers significant economic benefits. Recovering valuable metals and components from discarded electronics can reduce the costs associated with manufacturing new products. For instance, extracting metals from recycled electronics is often less expensive and less environmentally damaging than mining virgin materials. This not only lowers production costs but also stabilizes supply chains for critical materials.

Furthermore, the e-waste recycling industry creates job opportunities. As the volume of e-waste continues to grow, so does the demand for skilled workers in recycling facilities. This includes roles in collection, transportation, sorting, and processing of electronic waste. Investing in e-waste recycling infrastructure can stimulate economic growth by creating a new sector dedicated to sustainable practices.

Legal and Ethical Responsibility

Many countries have recognized the importance of e-waste recycling and have implemented regulations mandating the proper disposal and recycling of electronic waste. Compliance with these laws is not only a legal obligation but also an ethical one. Manufacturers and consumers alike have a responsibility to ensure that their electronic devices are disposed of in a way that does not harm the environment or public health.

Corporate responsibility initiatives often include e-waste recycling programs as part of their sustainability goals. By participating in these programs, companies can enhance their reputation, meet regulatory requirements, and contribute to global environmental conservation efforts.

Environmental and Health Impacts

The improper disposal of e-waste poses severe environmental and health risks. E-waste contains hazardous substances like lead, mercury, cadmium, and brominated flame retardants. When these toxic materials leach into the soil and groundwater, they can cause significant environmental damage. Furthermore, exposure to these substances can lead to serious health issues, including respiratory problems, skin disorders, and neurological damage.

Our Approach to Waste Management E-Waste

At JR Recycling Solution Ltd, we adopt a comprehensive approach to e-waste management, focusing on sustainability and efficiency. Our services encompass the entire lifecycle of electronic products, from collection and sorting to recycling and disposal. Here’s how we manage the process:

1. Collection and Sorting: We provide convenient collection services for households and businesses, ensuring that e-waste is gathered efficiently. Our sorting process separates different types of e-waste, facilitating more effective recycling.

2. Advanced Recycling Techniques: Utilizing state-of-the-art recycling technologies, we recover valuable materials such as gold, silver, copper, and rare earth elements from discarded electronics. These materials can then be reused in the manufacturing of new products, reducing the need for virgin resource extraction.

3. Safe Disposal of Hazardous Materials: We adhere to strict environmental standards to safely dispose of hazardous substances found in e-waste. Our processes prevent these toxins from contaminating the environment, protecting both ecosystems and human health.

4. Consumer Education and Awareness: We believe that informed consumers are key to effective e-waste management. Through educational campaigns and community outreach, we encourage responsible disposal of electronic devices and promote the benefits of recycling.

Effective Waste Management E-Waste Practices

Effective waste management strategies are essential for addressing the e-waste challenge. Several approaches can be implemented to enhance the efficiency of electronics waste recycling:

1. Extended Producer Responsibility (EPR): EPR policies hold manufacturers accountable for the entire lifecycle of their products, including end-of-life disposal. By incorporating recycling costs into the product price, producers are incentivized to design more sustainable and recyclable electronics.

2. Consumer Awareness and Participation: Educating consumers about the importance of e-waste recycling and providing convenient recycling options can significantly increase participation rates. Collection drives, drop-off points, and take-back programs are effective ways to encourage consumers to dispose of their e-waste responsibly.

3. Regulatory Frameworks: Governments play a vital role in regulating e-waste management. Implementing stringent regulations and standards for e-waste disposal and recycling ensures that these activities are conducted in an environmentally sound manner. Moreover, enforcing penalties for non-compliance can deter illegal dumping and encourage proper recycling practices.

4. Technological Innovations: Advancements in recycling technologies can enhance the efficiency and effectiveness of e-waste recycling processes. Innovative techniques such as hydrometallurgical and pyrometallurgical methods, as well as automated sorting systems, can improve material recovery rates and reduce environmental impacts.

The Role of Stakeholders in E-Waste Management

Effective e-waste management requires collaboration among various stakeholders, including manufacturers, consumers, recyclers, and regulators. At JR Recycling Solution Ltd, we work closely with all stakeholders to create a sustainable e-waste ecosystem:

- Manufacturers: We partner with manufacturers to develop eco-friendly product designs and recycling programs that facilitate easier end-of-life processing.

- Consumers: By offering easy access to recycling services and educating the public on the importance of e-waste recycling, we empower consumers to make environmentally responsible choices.

- Regulators: We comply with all relevant regulations and advocate for stronger e-waste management policies to ensure a greener future.

Conclusion

JR Recycling Solution Ltd. stands at the forefront of e-waste management, delivering innovative, sustainable, and effective solutions to tackle the growing challenge of electronic waste. Through our comprehensive e-waste management system, we prioritize environmental responsibility, ensuring the safe and efficient recycling of electronic products. Our approach not only mitigates the harmful impact of e-waste on the environment but also recovers valuable materials, contributing to the circular economy. By fostering partnerships with businesses, governments, and communities, we are committed to raising awareness and promoting practices that support a cleaner, greener future. JR Recycling Solution Ltd. is dedicated to continuous improvement and innovation in e-waste management, reaffirming our role as a leader in sustainable recycling practices. Together, we can make a significant difference in preserving our planet for future generations.