Gold extraction from old cell phones is a fascinating process known as urban mining. This guide will provide an in-depth look at how to get gold from old cell phones, covering everything from the gold content in devices to collection methods, disassembly, processing techniques, and environmental considerations.

Understanding Gold Content in Cell Phones

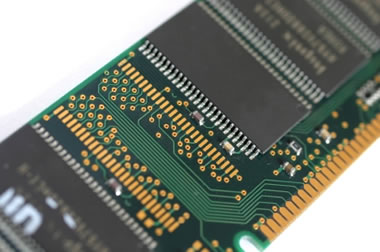

Old cell phones contain small amounts of gold, primarily found in their circuit boards and connectors.

- Average Gold Content: An average smartphone contains about 0.034 grams of gold, which may seem minimal but can accumulate significantly when considering the millions of discarded phones each year.

- Variability: The gold content can vary by model and age, with some high-end smartphones containing up to 0.1 grams or more.

- Other Precious Metals: In addition to gold, cell phones also contain other valuable metals like silver, palladium, and copper, which can be extracted during the recycling process.

The Collection Process: Gathering Old Phones

To effectively extract gold from old cell phones, a substantial collection is necessary. Here are some methods for gathering old devices:

- E-Waste Recycling Programs: Many municipalities and private companies run programs that encourage recycling of old electronics.

- Buyback Programs: Retailers often offer buyback programs where consumers can trade in old devices for store credit or cash.

- E-Waste Collection Events: Special events can be organized to collect old electronics from communities.

- Partnerships: Collaborating with businesses and organizations can facilitate bulk collection efforts.

Disassembly: Preparing for Gold Extraction

The disassembly of old cell phones is crucial for separating components that contain gold.

- Manual vs. Mechanical Disassembly: Phones can be taken apart either manually or through mechanical means.

- Sorting Components: Components are categorized into batteries, screens, plastics, and circuit boards. Circuit boards are the primary focus for gold recovery.

Processing Methods: Extracting Gold

Once the circuit boards are collected, several processing methods can be used to extract gold:

Chemical Leaching

This method involves using acids or other chemicals to dissolve gold from circuit boards.

- Process:

- Circuit boards are shredded into small pieces.

- A leaching solution (often cyanide or aqua regia) is applied to dissolve the gold.

- The gold-containing solution is treated to precipitate pure gold.

- Advantages: Highly efficient but involves hazardous chemicals.

Electrolysis

Electrolysis separates gold from other metals using an electric current.

- Process:

- Shredded circuit boards are placed in an electrolytic bath.

- An electric current is applied, causing gold to separate and collect on the cathode.

- Advantages: Less toxic than chemical leaching but may be less efficient.

Smelting (Pyrometallurgy)

This method involves melting components at high temperatures to extract precious metals.

- Process:

- Circuit boards are heated to over 1000°C in a furnace.

- Metals melt and separate based on their different melting points.

- Advantages: Can handle large volumes but is energy-intensive and may produce toxic fumes.

Environmental and Safety Concerns

The extraction of gold from old cell phones raises several environmental and safety concerns:

- Hazardous Chemicals: Many processes involve toxic chemicals that can be harmful if not handled properly.

- Pollution: Improper disposal of e-waste can lead to soil and water contamination.

- Regulations: Many countries have strict regulations governing e-waste handling and precious metal recovery to mitigate these risks.

Professional Recycling: The Best Approach

Due to the complexity and potential hazards involved in gold recovery, it is generally recommended to leave this process to professional recycling companies. These facilities have the necessary equipment and safety measures to handle the extraction responsibly.

Economic Viability: Is It Worth It?

Extracting gold from old cell phones is generally only cost-effective at a large scale.

- Yield: It is estimated that 1 ton of cell phones (about 10,000 devices) can yield around 340 grams of gold.

- Market Prices: The profitability of the process depends on current gold prices, operational costs, and the efficiency of the extraction methods.

Legal Considerations

In many regions, there are laws governing e-waste disposal and precious metal recovery. Companies involved in this industry often require permits and licenses to operate legally.

Future Developments in Gold Recovery

Research is ongoing into more environmentally friendly extraction methods. Some innovative approaches include:

- Biomining: Using bacteria to extract gold from electronic waste.

- Sustainable Techniques: Developing methods that minimize the use of toxic chemicals and improve recovery rates.

Conclusion: The Importance of Responsible Recycling

While it is possible to extract gold from old cell phones, the process is complex and can pose environmental risks if not done correctly. The most responsible action for individuals is to ensure that old phones are properly recycled through certified e-waste recycling programs. This not only helps recover valuable materials but also contributes to a more sustainable future.

Summary Table: Key Points on Gold Extraction from Cell Phones

| Aspect | Details |

| Gold Content | Average of 0.034 grams per phone, varies by model |

| Collection Methods | E-waste programs, buyback services, collection events |

| Disassembly | Manual or mechanical, focusing on circuit boards |

| Processing Methods | Chemical leaching, electrolysis, smelting |

| Environmental Concerns | Hazardous chemicals, pollution, regulatory compliance |

| Economic Viability | Cost-effective at large scale, approximately 340 grams of gold per ton of phones |

| Legal Considerations | Permits and licenses often required for e-waste handling |

By understanding the process of how to get gold from old cell phones, individuals and businesses can contribute to the circular economy and promote sustainable practices in electronic waste management.

Leave a Reply